Exploring the Impact of Plastic Mold Companies in the Business Ecosystem

In the dynamic world of manufacturing and production, plastic mold companies play a crucial role by offering innovative solutions and designs that meet the diverse needs of various industries. With advancements in technology and an increasing demand for high-quality products, these companies are not just suppliers; they are partners in the growth and success of many businesses.

The Significance of Plastic Mold Companies

Plastic moulding is a manufacturing process that involves creating parts by injecting molten materials into a mold. This technique allows for the efficient production of complex shapes with high precision. The importance of plastic mold companies can be observed in their contributions to:

- Manufacturing Efficiency: Companies utilize advanced techniques to reduce waste and lower production costs.

- Rapid Prototyping: Rapid development and testing of prototypes help in faster time-to-market.

- Customization: These companies can produce tailored solutions for unique design requirements.

- Quality Control: Implementing stringent quality checks ensures compliance with industry standards.

Key Processes in Plastic Molding

Understanding the processes involved in plastic molding is essential for evaluating the capabilities of plastic mold companies. The primary methods include:

1. Injection Molding

This method involves injecting molten plastic into a mold under high pressure. It is ideal for producing large volumes of parts swiftly. The process can create detailed designs and is widely used across various sectors.

2. Blow Molding

Blow molding is primarily used for making hollow plastic products, such as bottles. In this process, air is blown into a heated plastic tube, forming a hollow shape that conforms to the mold.

3. Rotational Molding

This technique involves rotating a mold to distribute plastic. It is particularly useful for creating large, hollow parts that require a strong, uniform wall thickness.

4. Thermoforming

Thermoforming processes involve heating a plastic sheet until pliable and then forming it into a specific shape by using a mold. This method is effective for creating trays, packaging, and various containers.

Advantages of Partnering with Plastic Mold Companies

Collaborating with plastic mold companies offers numerous advantages for businesses across multiple sectors:

- Cost-Effectiveness: Bulk production in injection molding significantly reduces the average cost per unit.

- Consistency: High precision in molding ensures that each part meets strict tolerances.

- Material Selection: A wide variety of plastic materials allows businesses to select the best option for their needs, whether it be strength, flexibility, or cost.

- Innovative Solutions: Many plastic mold companies invest in research and development, introducing new techniques and materials that enhance product capabilities.

Industries Benefiting from Plastic Mold Companies

The versatility of plastic molding makes it applicable across a multitude of industries, including:

1. Automotive Industry

The automotive sector heavily relies on plastic mold companies for the production of components such as dashboards, door panels, and various internal parts. The lightweight nature of plastics, combined with their ability to reduce vehicle weight, contributes to improved fuel efficiency.

2. Consumer Goods

From kitchenware to personal care products, consumer goods manufacturers utilize plastic molds to create aesthetically pleasing, durable, and functional products. Custom designs allow brands to differentiate themselves in crowded markets.

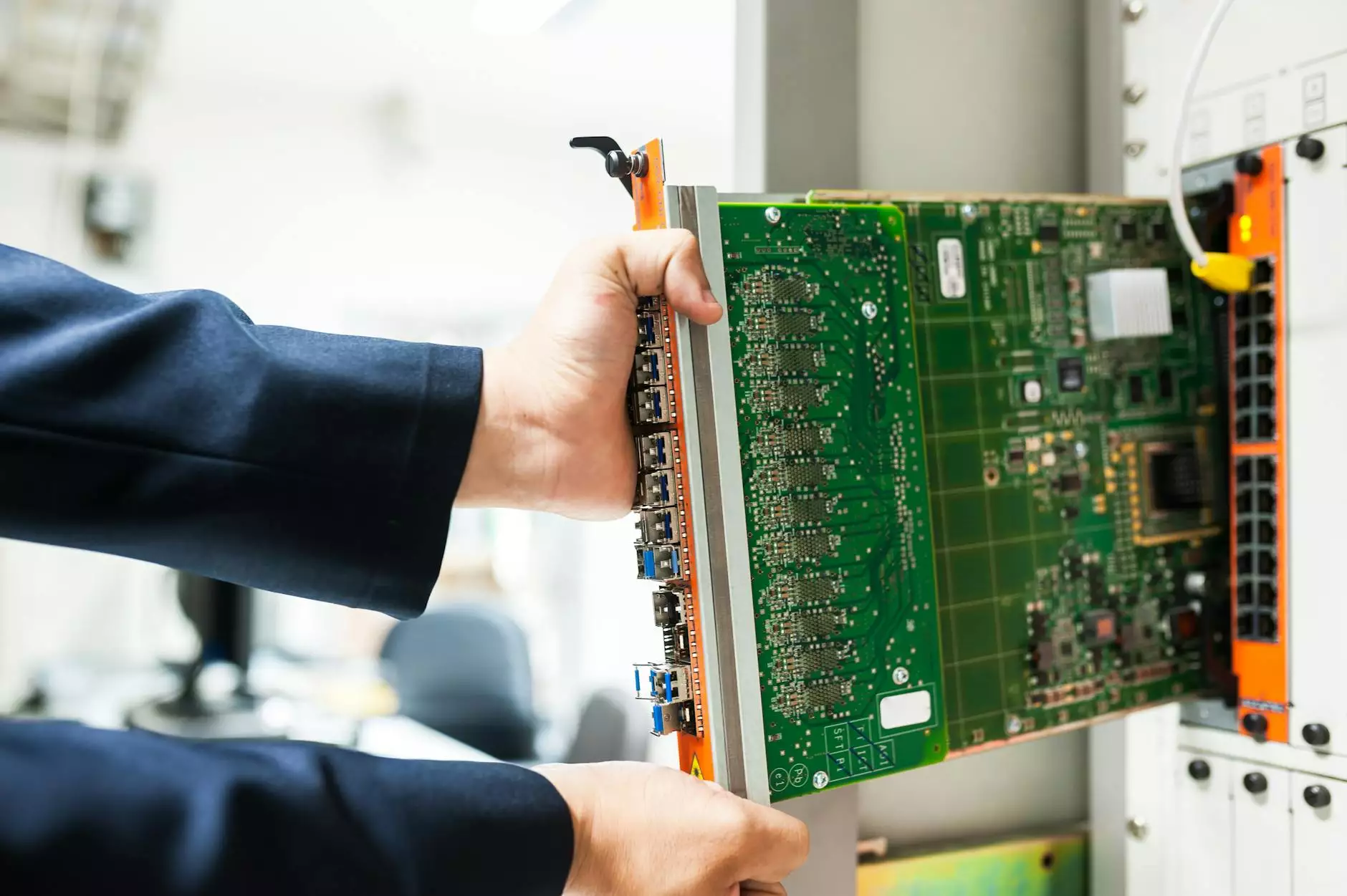

3. Electronics

In the electronics industry, plastic molding is fundamental in producing casings for devices. These companies help ensure that each component meets safety and performance standards while providing a sleek appearance.

4. Medical Devices

Plastic mold companies play a critical role in the medical field by producing components for devices and instruments. Precision molding is essential here due to regulatory requirements related to safety and functionality.

Choosing the Right Plastic Mold Company

When selecting a plastic mold company for your business needs, consider the following factors:

- Experience and Expertise: Choose a company with a proven track record in your industry.

- Technology and Resources: Look for companies using the latest molding techniques and machinery.

- Customer Service: A dedicated support team can help you navigate the complexities of the molding process.

- Pricing and Turnaround Time: Competitive pricing and reliable production timelines are essential for maintaining your own business schedules.

The Future of Plastic Mold Companies

As sustainability becomes increasingly important, plastic mold companies are adapting by exploring bioplastics and recyclable materials. Innovations in molding technology such as 3D printing and smart manufacturing also show promise in revolutionizing traditional practices.

Emphasis on Sustainability

Many companies are now prioritizing environmentally friendly practices. This includes:

- Implementing recycling programs for plastic waste.

- Researching biodegradable materials.

- Investing in energy-efficient machinery.

Embracing Technology

The integration of technology in manufacturing processes is paving the way for smart factories. Automation and data analytics will play significant roles in optimizing production efficiency and quality control.

Conclusion

In summary, the role of plastic mold companies is indispensable in the contemporary business landscape. As industries continue to evolve, these companies not only provide the necessary tools to manufacture high-quality products but also contribute to innovation and sustainability efforts. By partnering with a top-tier plastic mold company, businesses can leverage their expertise, cutting-edge technology, and industry-specific knowledge to drive growth and maintain a competitive edge.

To further explore the benefits and opportunities that can arise through collaboration with seasoned plastic mold experts, consider reaching out to Deep Mould. As a leading name in the industry, we are dedicated to helping businesses achieve their manufacturing goals efficiently and effectively.